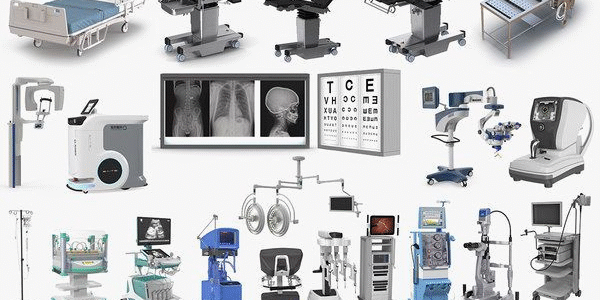

In the healthcare industry, the functionality and quality of medical equipment are naturally the focus of attention. However, often overlooked are the “unsung heroes”—medical casters. As essential components of medical devices, the choice of medical casters directly impacts the stability, mobility, and safety of the equipment. Therefore, when purchasing medical casters, hospital administrators and procurement officers must pay close attention to several critical factors.

1. Types of Medical Casters

Medical casters generally fall into two main categories: fixed and swivel casters. Fixed casters are typically used for equipment that needs to stay in one position, such as large medical devices, while swivel casters are suitable for equipment that needs frequent repositioning or movement, such as hospital beds and carts. Choosing the right type of caster based on the specific needs of the equipment can significantly improve operational efficiency.

2. Materials Used in Medical Casters

The material of the caster is a crucial factor that affects its performance. Common materials include rubber, polyurethane, and nylon. Each material has its unique advantages and applications. For instance, polyurethane casters offer excellent wear resistance and shock absorption, making them ideal for equipment that requires extended movement. On the other hand, rubber casters perform well in terms of noise reduction and shock resistance, which makes them suitable for use in environments like operating rooms that demand quiet operation.

3. Load Capacity and Durability

Medical equipment often needs to support significant weight, especially for hospital beds and other large devices. Therefore, when selecting medical casters, it is essential to ensure they have sufficient load-bearing capacity. Casters that lack proper load capacity are prone to wear and may compromise the stability of the equipment, presenting potential safety risks to both patients and healthcare workers.

4. Convenient Locking Mechanism

In a hospital’s busy environment, a reliable locking mechanism is crucial for medical casters. A secure locking system ensures that equipment remains stationary after being moved, preventing unintended shifts that could lead to accidents. High-quality medical casters are typically equipped with effective locking devices to ensure that equipment stays stable when not in use.

5. Anti-Static and Antimicrobial Properties

In certain medical settings, anti-static and antimicrobial features are essential. Static electricity can interfere with sensitive medical equipment, while antimicrobial properties help reduce the growth of harmful bacteria on equipment surfaces. Choosing medical casters with these features can further enhance the safety and hygiene levels of medical devices.

Conclusion

While medical casters may not be the most noticeable components of medical equipment, they are critical to ensuring the smooth operation of these devices. Choosing the right medical casters not only improves the overall user experience but also enhances hospital efficiency and patient safety. As such, hospitals should carefully consider the quality and functionality of medical casters when procuring medical equipment to ensure every detail contributes to better patient care.